You’ve made the decision that your SLC-500 platforms are unsustainable, but now what? Mapping out a path forward is challenging and requires planning to be successful. As in most controls projects, two areas of concern must be addressed: software and hardware.

You’ve made the decision that your SLC-500 platforms are unsustainable, but now what? Mapping out a path forward is challenging and requires planning to be successful. As in most controls projects, two areas of concern must be addressed: software and hardware.

Software Considerations

Let’s address the software first. There are two basic approaches.

- Rewrite the code or,

- Use Rockwell’s conversion tool.

Here are the pros and cons of each, along with a 3rd hybrid option. Click the (+) below to expand.

Pros

- A lower cost solution as it takes less time to execute.

- Minimizes the risk of bad logic.

Cons

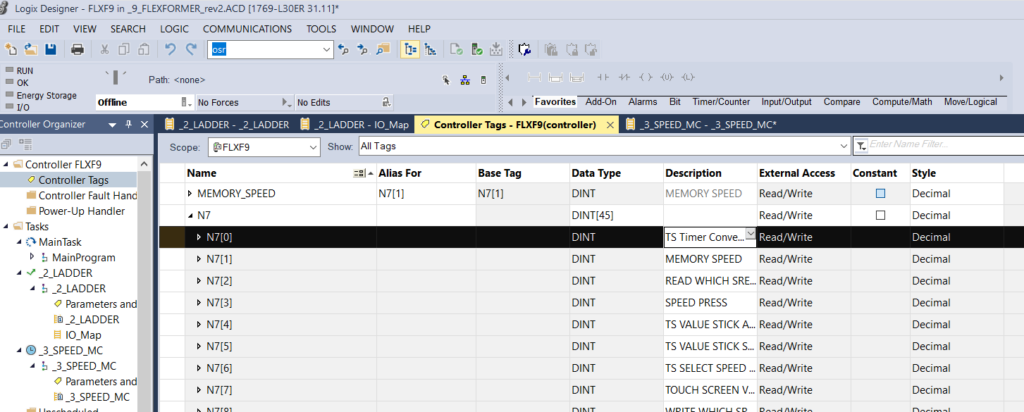

- The tag names use a format that resembles the old SLC-500 file structure. The old address of N7:0 will become N7[0].

- Though tag descriptions can be used when working with HMIs or messaging with other PLCs, N7[0] doesn't mean much.

- Does not take advantage of new programming standards or commands

Pros

- The opportunity to take advantage of the latest software commands, standards and technologies allowing you to increase performance.

- Because you can use readable tag names, the entire program becomes much easier to follow.

- HMI development is more understandable and straightforward.

Cons

- The additional time it takes to rewrite the code will be more expensive than conversion.

- Some risks involved in the recreation of the logic code.

Approach the software with a hybrid approach, using the conversion tool but then rename all the tags

Pros

- Less expensive than a total rewrite.

Cons

- More expensive than a path that only uses the conversion tool.

Hardware Considerations

Second, let’s look at the hardware. There are three basic options. But first, determine the platform that is best to replace the SLC 500 with. Based on the I/O count and complexity, a CompactLogix platform may offer a more practical solution. However, with future expansion and possible consolidation of systems, a ControlLogix platform may be best.

- The first is to replace the SLC-500 processor with an Ethernet card that turns the existing rack into remote I/O.

- The second is to use Rockwell’s conversion kit to link a new CompactLogix Processor and I/O modules to the old 1746 I/O using Rockwell’s 1492 cabling systems. Only available with CompactLogix.

- The third option is to upgrade all the 1746 cards and chassis, replacing it all with a CompactLogix Processor and I/O. In essence a complete hardware conversion.

Pros

- Little to no downtime needed for rewiring.

- Minimal hardware costs. No new CompactLogix I/O cards needed.

- No bridges are burned. Can return to the original SLC-500 processor very quickly.

Cons

- The obsolete 1746 I/O remains in place.

Pros

- Little to no downtime needed for rewiring.

- Minimal hardware costs. No new CompactLogix I/O cards needed.

- No bridges are burned. Can return to the original SLC-500 processor very quickly.

Cons

- The obsolete 1746 I/O remains in place.

Pros

- Eliminate all legacy components.

- Easier to troubleshoot moving forward.

- Less cost for hardware since you don’t have to buy the conversion kit.

Cons

- Requires the most downtime.

- Every wire must be re-terminated.

- A complete I/O checkout is required.

LSI Listens

Whether you have a stand-alone controller, a small network of controllers or a large complex interconnected control system, LSI can help. We begin by listening to your unique needs, working to understand your processes and objectives. Then we help you to develop and execute a roadmap for upgrading your hardware and optimizing your processes. Learn more about our process below.

Whether you have a stand-alone controller, a small network of controllers or a large complex interconnected control system, LSI can help. We begin by listening to your unique needs, working to understand your processes and objectives. Then we help you to develop and execute a roadmap for upgrading your hardware and optimizing your processes. Learn more about our process below.

The right people, platforms, and outcome for any project.

LSI Can Help You

Let LSI listen to your challenges today, and we’ll work together to write a success story for you.

Not Quite Ready? Read Some of Our Success Stories