LSI has sold hundreds of systems to the HVAC, Elevator, Generator and Appliance industries for over the past two decades.

We have significant experience with assembly line automation and product testing from critical component verification, functional run test, integrity testing, liquid charging, and lay-in/WIP stations.

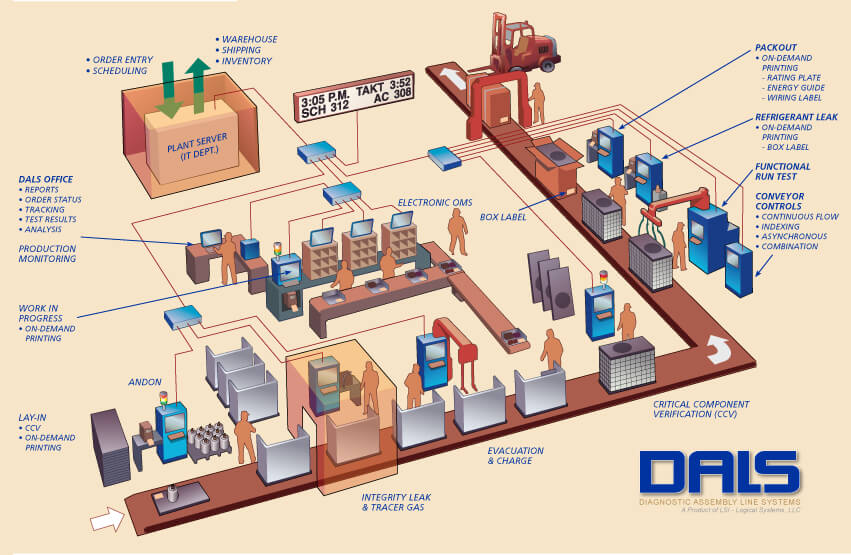

DALS Stations

Fundamentally there are two types of DALS testing stations:

- An Assembly Process station contributes to the progressive assembly of the product.

- A Test Qualification station which evaluates the product at a particular point in the assembly through a series of applied tests where measurements can be taken and compared to pre-set high parameters and low parameters.

It is possible to have both types of stations combined in some format into a single process.

DALS stations can be used in a stand-alone process or networked with other DALS stations providing for an integrated quality solution. The minimum hardware DALS configuration is a networked PC with a barcode scanner and/or printer.

Typically DALS stations incorporate I/O systems that are installed inside the PC in a slot or installed exterior to the PC in a rack-mounted system. Advanced DALS stations have the I/O systems plus other specialized test systems connected to the PC through serial communications.

DALS Software

DALS software is a complete production package designed for the plant floor.

Within DALS is a suite of programs that interact to provide a solution in a variety of assembly operations and testing qualifications. DALS is a .NET based software package that resides on a personal computer (PC) and operates with the latest Microsoft Operating Systems.

DALS stations share their connectivity on the plant floor through a common SQL database.

Each DALS station type, located on the plant floor, is stored in the database with its plant floor location; typically plant floor locations are defined by Line Number or Line Name. All DALS stations that share the same assembly line, intercommunicate to provide unit assembly progress and status. As the assemblies proceed from one DALS station to the next, “real-time” test data is generated and saved in the database. DALS’ bottom-up approach gets production information “up to” manufacturing reporting services or other production resources providing real-time information to supply chain management systems.

DALS is designed to operate with a stand-alone SQL database on a server allowing users to access and use “canned” reports embedded in DALS or use Microsoft’s SQL Server Reporting Services or other 3rd party software that can access SQL databases. Additionally, DALS can report to SAP or an existing AS400 or management computing platforms.

Each product being assembled must pass a DALS station’s assembly process or test qualification before it is allowed to continue to the next station.

Every time a product under assembly (PUA) is scanned in a DALS station, it is evaluated to determine if all previous tests or required processes have occurred and passed within proper parameters. This is called process interlocks. Only PASSED PUA’s can advance through the process.

DALS Integration

How DALS can be integrated into a refrigerant-based assembly process:

Assembly Line

Lay-In Station

Operates in either “paperless” or “scan” mode. Paperless mode prints bar codes on demand as the operator selects from a daily build schedule. In “scan” mode, pre-printed bar code packets are scanned from a predetermined build stack.

Critical Component

Critical Component Verification (CCV) stations ensure the correct part installation electronically, validating against the Model Number’s Bill of Material (BOM). CCV stations can be dispersed along the assembly line in any location.

Leak Test Station

Automatically combines a containment integrity burst test with a tracer gas leak test using dry air or 100% nitrogen up to 600 psi. Tracer gasses can also be monitored using equipment specifically designed for specific gasses.

Evacuation And Charging

Automatically evacuates the unit to a very low micron level. Performs a drop/decay check. Charges the unit with refrigerant weights stored by model numbers, all in a single high side connection and low side connection.

Run / Test Station

An automated test/verification station designed to run a variety of tests including Hi-Pot, Ground Bond, Ground Continuity, Line Leakage, Low Voltage Wiring, Peak Amperage Start, Voltage Start, Run Amps, Run Voltage, Run Power, Temperature Monitoring/Trending, Harness Wiring Continuity, etc… Assembled unit validation and operations checked before boxing/packaging.

Refrigerant Leak Test

Verifies leak detection against the unit’s Serial Number through integration with a variety of detectors by utilizing their analog output or serial port.

Packout

Verifies and validates all tests have occurred and have passed and ready for the warehouse or for shipping. Automatically tie Packout to a final process; such as: strapping machines, packaging systems, or bar-code printers so ONLY 100% ready units may be shipped.

Sub-Assembly Line

Work In Progress

Work In Progress (WIP) triggers a start build process of off-line sub-assemblies for units being built on the main assembly line. Removes sub-assembly when mainline unit passes downstream assembly process. WIP mimics the order process used in the drive-thru fast food industry.

EOMS Station

Electronic Operational Method Sheet (EOMS) provides unit model number textual information, electronic images, video, PDFs, and CAD drawings to the fingertips of the operator to access while assembling. EOMS allows for real-time updates to be deployed to the factory floor in seconds.

Additional Production Essentials

DALS Office

Program suite providing:

• Security Editor

• Report Generation

• Configurations

• Unit Data Viewer

• Test Program Editor

• More

Production Monitoring

Displays real time production status of the assembly line and all test stations during a shift. Provides PASS/FAIL unit counts on each test station and TAKT status. Schedule driven.

TAKT Sign

Monitors located along the assembly line are constantly updated with TAKT information during a shift. Real-time progress of Scheduled vs. Actual units built is displayed throughout the shift.

ANDON System

Provides direct factory floor notification and can be automatically activated through programmed faults or can be manually activated by the operator with a field-mounted selector switch. Both management and production can be instantly notified of production equipment failure.

Accessories

• OnDemand Printing

• Ambient Temperature Compensation

• Smart Scan

Need More Information?

Although DALS offers a complete assembly line solution, partial- or single-station installations are very common. Product choice is directly driven by the customer’s needs. Then as other assembly needs or long-term goals are implemented, additional products are added leveraging DALS’s flexibility.