Consistency counts, especially when it comes to coffee production success. Operations of all sizes depend on their roaster controls to deliver consistent taste and color, roast after roast.

Leading coffee companies turn to the team at LSI for roaster control support and process optimization. As an outcome-driven systems integrator, we start every project by listening, learning, and understanding our clients’ processes and business drivers. By combining that understanding with our knowledge and industry experience, we can provide innovative coffee production solutions. With a combined 60+ years of roaster experience and 150+ years of coffee controls experience, LSI is eager to help with all brands of OEM roasting equipment.

Roaster Control Services and Support

The LSI Coffee team offers complete roaster control services including:

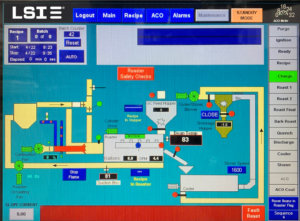

Click thumbnail to enlarge image. Roaster control design, including safety compliance

- Support or upgrade of OEM control software

- Installation and commissioning support for numerous coffee roasters including Probat, Neuhaus Neotec, Scolari, Diedrich, and Burns

- Troubleshooting and tuning of existing roaster systems

- Advanced roaster control algorithm design

- Development of roasting profiles with up to 20 stages controlling time and temperature

- Recipe conversion from existing roaster models to next-generation roasters

- Controls are PC-based with custom HMI software and Interactive Roast Curve Following™ (IRCF)

- Systems include a VPN for training and support purposes

- Training of client personnel on:

- Roast profile development

- Preventive maintenance

- Manufacturing of UL508A panels

Systems Integration Advantage

In addition to roaster controls, LSI provides support for all coffee production equipment and systems. Whether it’s roasting controls or software handshakes with handling, grinding, green batch blending, post-roast blending, or packaging, LSI draws on over 35 years of system integration experience to provide plant-wide support.