How Can Our HVAC Manufacturing Process Identify Faulty Control Circuit Boards Before Final Unit Testing?

What Our Client Said

Our final assembly plant for HVAC systems is experiencing a growing number of control circuit board failures that only manifest themselves during final testing of the assembled product (using an LSI DALS End-of-line test station). Our DALS Office reporting program helped us to identify this trend and prompted us to look closely at the source: circuit boards that come from a partner facility. The time it is taking us to replace their faulty products is crippling the productivity of our final production line.

What We Heard

We need to test these components before they are installed into the final HVAC units. When a faulty board makes it all the way to final testing it forces us to spend time removing the control board, re-installing another board, then performing a retest before the completed unit can be released for shipment. Then we need to spend time sending the board back to the manufacturer. We need to know that these control circuit boards work before we install them, period.

What We Did

First, our LSI-DALS team listened closely to the customer’s challenge.

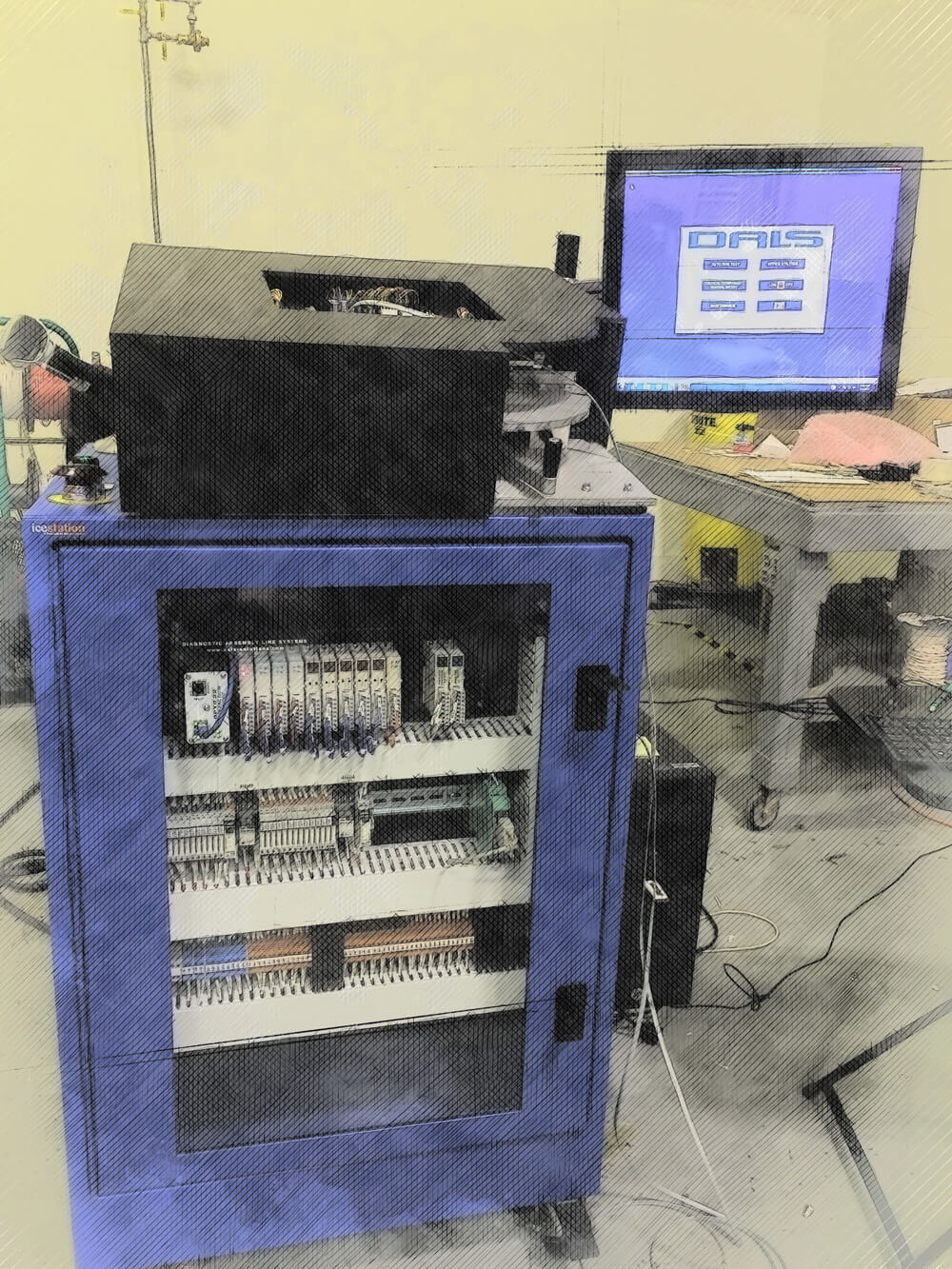

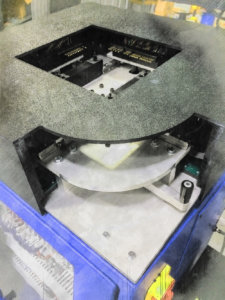

Then we designed a stand-alone tester that completely assesses all of the circuit board’s functionality and saves its test data via its serial number to an SQL database before leaving the sourcing facility to be shipped to the final assembly plant.

The operator simply inserts the control circuit board into the DALS test stand, and the test station simulates input signals and produces the output signals as if the board was in a fully assembled unit. As a result, faulty control circuit boards can be identified long before they are installed.

The operator simply inserts the control circuit board into the DALS test stand, and the test station simulates input signals and produces the output signals as if the board was in a fully assembled unit. As a result, faulty control circuit boards can be identified long before they are installed.

This major HVAC manufacturer now utilizes three DALS systems developed by LSI:

- DALS control circuit board testing at the source

- DALS office process management and monitoring

- DALS end-of-line testing

The Results Speak For Themselves

Improving productivity

Improving productivity

Before LSI’s DALS testing system virtually eliminated the problem of faulty boards in final units, as many as seven malfunctioning circuit boards were identified each day. The results were totally unacceptable, as the process was interrupted and resources were diverted to the time-consuming chore of replacing and returning faulty components.

Saving time and money

Replacing each bad circuit board took 30-45 minutes. Now that these issues are rare, the customer’s production line is able to function as intended, improving their efficiency and profitability.

Completing more units per day

By implementing the LSI DALS test station at the circuit board manufacturer’s facility, the final assembly process saw a TAKT gain of nearly 10%! That’s 10% more units completed and delivered each and every day

LSI Listened

LSI listened, then our DALS team put their expertise, experience and resources to work. Being part of a complete control, automation and integration provider allows them to develop complete DALS solutions. Without the constraints imposed by OEM obligations or geographical limitations, LSI is able to imagine these answers with the customer in mind, then implement them in the most logical, effective way possible.