We Need To Integrate Six Fanuc Robots Into Our Forging Process That Also Consolidates All The Disparate Safety Systems Into A Single Supervisory Safety PLC.

What Our Client Said

Our automated forge system produces safety-critical suspension components using our own trademarked process. This process is very time-critical and must be monitored to keep parts within set parameters due to complex properties of forging. The parts will need to be tracked and laser etched due to safety requirements. The complete system will need to run in full-auto, semi-auto, and manual mode to always keep production running. Unfortunately, our plant runs several PLC Platforms within the production cell that lack a master control and this translates to negative OEE impacts with slower cycle times and difficult troubleshooting that leads to less production.

What We Heard

We need an overall control system and strategy that provides for supervisory control over the entire production cell, which provides “plug-and-play” flexibility as production needs change without a decrease in OEE. Even while in automatic mode the operator will need to be able to monitor and provide input to the line without stopping the line. The system design must support the addition of new parts without negatively impacting rate.

What We Did

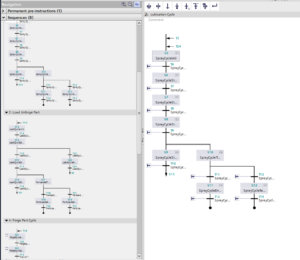

LSI leveraged its in-depth Siemens knowledge to structure a well-organized program by using User Defined Data Types on top of multi-instances function block programming to provide a strong foundation that was easy for the plant technical team to learn and troubleshoot.

Our team of engineers stripped the system down to its core functions to restructure and rebuild the program for full supervisory control of machines and robots to push efficiency to new levels. The goal was to keep the code simple by using basic, reusable building blocks of logic to allow the plant to maintain the system with in-house personnel.

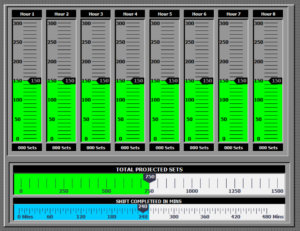

LSI redesigned the system both mechanically and electrically to address all aspects of the customer’s needs: high-level graphics and animations that help to define/rectify faults due to the complex process; complete production statistics tracking for each shift; a completely scalable recipe handler; and tool changes for the robots. Mechanically, the system work flow was re-designed to allow the operators to work more efficiently while supporting faster production speeds and quicker recovery from process upsets.

LSI provided:

- Project management

- Process engineering

- Electrical engineering

- Mechanical engineering

- Controls and automation engineering

- Siemens TIA Portal V13

- Siemens 1517 Safety Controller

- Specialized recipe handling software

- Comprehensive control testing

- Integration and Interface to existing OEM machines

- TÜV Safety Audit and Safety Engineering.

The Results Speak For Themselves

Improved foundry traceability and product quality tracking

Improved foundry traceability and product quality tracking

- Upgrade and consolidation of the PLC and HMI platforms throughout the plant enabled consistency across the networks. This consistency helps with foundry traceability and product quality tracking.

- Improved OEE of the system by 25%, exceeding the client’s expectations.

Increased all safety aspects

- LSI provided two levels of safety inside this system. Level 1 ensures the safety of the operator due to direct interaction with machines in manual or robots in auto. Level 2 ensures machine safety due to the robots working in shared and overlapping areas.

Maximized flexibility

- New manual mode allows operators to safely manually forge and trim parts in one area of the cell while the rest of the cell in in auto. This also allows small production parts to be run in manual, due to limited capital for robot tools and programming. The cell is divided into sections. An operator can manually fill any of the sections and still run production. Basically the operator can always run production no matter what state the machine is in.

- The installed recipe handler utilizes control set points to improve overall control of the robot cell and production line.

Future proofing

- The recipe handler allows future recipe downloads from the HMI application to forge multiple part variations in the cell. LSI’s mission is to standardize an application specifically for the end user to provide a strong foundation and blueprint so that they can support the system internally.

LSI Listened

LSI listened, asked questions, then developed a strategy for combining the Fanuc robot cell and the Siemens controllers to not only improve the production process, but to also set the groundwork for consolidating and simplifying the communication between PLCs throughout the facility.

This customer came to LSI because they needed to not only improve their production process, but also to take the first steps toward a more consistent, productive, efficient set of controls throughout their entire operation. Who do you contact when you need to solve one complex challenge and build in future solutions to future challenges at the same time? An independent system integration team that puts all of the experts in one place with the customer’s best interest in mind. In other words, you contact LSI.