We Need To Build A Flexible Line At Our Chemical Plant In China That Can Increase Our Production Capabilities And Lower Costs At The Same Time.

What Our Client Said

The market is becoming more competitive, and the labor rate continues to rise. At the same time, our clients need us to increase our capacity. We have manual production lines but need to add automated lines that produce 60,000 tons per year to keep up with the requirements of our clients.

What We Heard

We need an automated production line, and it needs to be more than just new – it needs to be better, giving us more capacity and more information without hurting our profit margins, creating unreasonable downtime or compromising our security.

What We Did

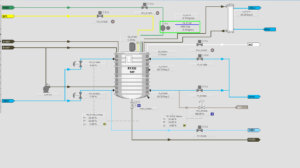

LSI started by listening, then we put that information to good use. The new line allows operators to better manage productivity by analyzing critical setpoints and tracing Historian data. It uses intuitive graphics and multilanguage flexibility. Recipes are easy to use and add, and the system reports temperatures, pressures, setpoints, valve states and more (all logged in FactoryTalk). Customized Batch Reports are automatically generated at the end of each batch. Authorized personnel can remotely access the HMI using a browser on their computers, phones and tablets. The alarm system was also improved.

LSI started by listening, then we put that information to good use. The new line allows operators to better manage productivity by analyzing critical setpoints and tracing Historian data. It uses intuitive graphics and multilanguage flexibility. Recipes are easy to use and add, and the system reports temperatures, pressures, setpoints, valve states and more (all logged in FactoryTalk). Customized Batch Reports are automatically generated at the end of each batch. Authorized personnel can remotely access the HMI using a browser on their computers, phones and tablets. The alarm system was also improved.

Finally, the new automated line is easily expandable thanks to a Rockwell PlantPAx DCS (adding new devices is as easy as “cut and paste”).

LSI provided:

- Project management

- Electrical design

- Panel fabrication

- PLC, HMI and Batch programming

- Field installation with cable tray and instruments

- On-site commissioning

The new control system consisted of:

- ControlLogix controller

- Remote 1794 Flex I/O communicating via ethernet

- PowerFlex VFD 755 and 525 communicating via ethernet

- Schneider soft starters

- Three operator stations running FactoryTalk SE Client l

- HMI Server running FactoryTalk SE

- Server running batch application and Historian

The Results Speak For Themselves

Product flexibility means new lines can evolve

LSI leveraged productivity tools that shorten production time and minimize human error. The production line realized improved automation and control, as well as increased production rates by 25%. We also simplified the manual operation and improved reliability. Now the time-consuming and error-prone tasks associated with manual operation is reduced to zero.

Minimized downtime

Users can now view relevant data in an easy-to-understand format. When outages are planned, maintenance is more productive thanks to easy device integration and diagnostics.

Fewer project risks

We utilized proven industry standard technology to bring a significantly improved user experience to operations and maintenance.

Reduced overall costs

By partnering with Rockwell Automation for ongoing support and training, LSI was able to maximize every dollar spent.

Easier to use

Users can now manage abnormal situations with easy navigation and reliable safety systems.

Improved productivity

The new system features intuitive graphics and multi-language support.

Optimized throughput

The facility now gets the most from the equipment with adaptable control strategies and advanced process control models.

Reduced security risks

Advanced components take advantage of “defense-in-depth” layers to secure manufacturing assets.

Innovative improvements

The system now includes mobility, virtualization and network technologies.

LSI Listened

LSI listened, then we went to work. Our experienced engineers and developers planned out a new automated production line that not only met customer expectations for improved control, increased capacity and strengthened security, but allowed for future expansion with just a few minor adjustments as well.