What Can We Do To Stop Our Robotic Case Packers From Dropping And Failing To Pick-Up Product Which Is Slowing Down Our Throughput?

What Our Client Said

Our robotic margarine tub case packers have started failing to pick-up margarine tubs several times a shift. It’s significantly impacting our line throughput, not to mention creating a significant cleanup effort and source of contamination. We received a quote from the OEM to redesign the system, but the cost – $20,000 per head times 36 heads – would be crippling to our bottom line.

What We Heard

We know from your previous work that LSI has the engineers, resources and ingenuity to solve unique problems with individually developed solutions. We also know that being independent of any OEM lets LSI optimize resources by choosing or creating exactly the right components for each solution without agendas or bureaucratic limitations.

What We Did

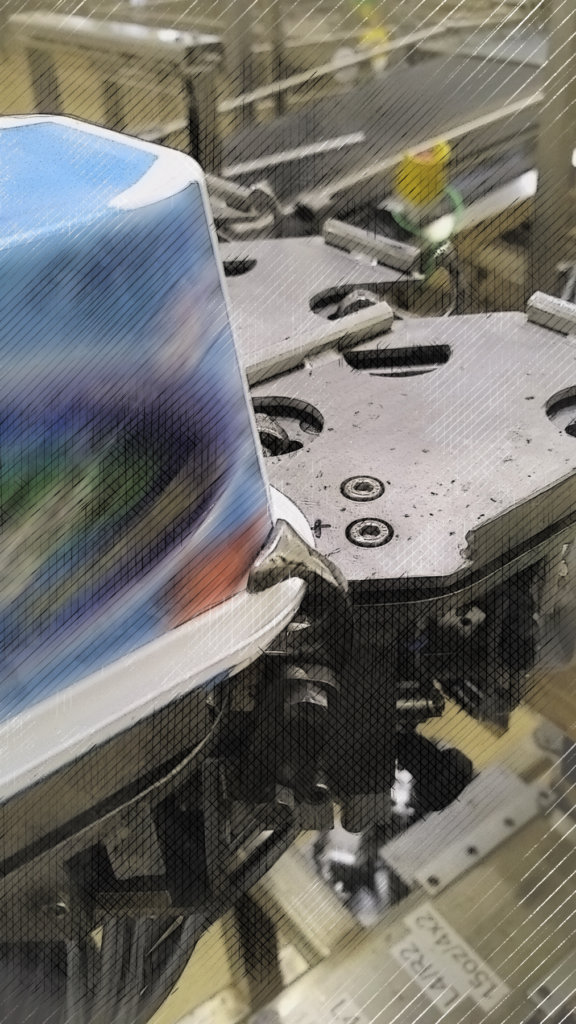

An LSI engineer visited the site, carefully listened to the client’s concerns and reviewed the operation of the case packers. After monitoring the line operation, it was suspected that one small component on the robot end effectors or “fingers” was not properly designed and could not repeatably and reliably capture the margarine tubs.

An LSI engineer visited the site, carefully listened to the client’s concerns and reviewed the operation of the case packers. After monitoring the line operation, it was suspected that one small component on the robot end effectors or “fingers” was not properly designed and could not repeatably and reliably capture the margarine tubs.

LSI requested that spare heads be shipped to our in-house machine shop for our machine designers to review. They determined that the multi-piece design of the original fingers was at the root of the problem. The original manufacturing process would simply not produce fingers to a tolerance sufficient for the task. LSI’s machine shop and designers redesigned a new, one-piece finger so that placement of the end of the finger became much more manageable and repeatable, providing a larger contact area with each tub. Pick-up reliability would be dramatically improved. Utilizing one of LSI’s machine shop’s CNC machines, the newly designed finger was programmed and produced. Making new fingers in the future, should one be broken, would be a simple matter of re-running that part number and producing a duplicate.

We proposed to test the prototype “finger” design on a single head, and the client agreed. The experiment was a success, and the client immediately rush ordered new hardware for the remaining case packer heads.

LSI provided:

- Mechanical engineering

- Research and testing

- Design

- CNC machining

- CNC G-Code

- Custom-built components

- Installation

- Support

The Results Speak For Themselves

Improved throughput

The redesigned case packer heads significantly increased the production line’s efficiency by improving the reliability of the robotic case packer.

The redesigned case packer heads significantly increased the production line’s efficiency by improving the reliability of the robotic case packer.

Reduced cleanup and contamination

Spilled margarine was a problem in many ways. It caused stoppages and it required cleanup, but it also presented issues due to the contamination from margarine getting into the equipment. When the case packer stopped miss-handling tubs, everyone benefited, from the line operator and maintenance to the plant manager.

Significant cost savings

Not only did this redesign improve overall line efficiency, it was completed at a fraction of the cost than that quoted by the OEM. Overall, LSI saved the client more than $500,000 (and this is simply looking at the machine changes required – it doesn’t account for the savings achieved through greater line OEE).

LSI listened

LSI listened, then developed a custom solution by utilizing the experienced professionals in our cutting-edge machine shop. Because LSI is independent and not owned by a manufacturer, we were able to put the customer’s needs first – selecting the best solution to meet the client’s needs.