A partnership built on trust – soy protein manufacturer IFF Nourish Protein Solutions in Memphis, TN, partners with LSI for long-term controls upgrades and more.

As a systems integrator, earning a client’s trust is critical to building a long-term client relationship. Trust takes time and effort to earn, often starting with a service call or small project to demonstrate capability and competence. Many of LSI’s longest and most valued relationships, including the one described below, started small and confirms LSI’s approach to every project – LSI Listens.

About IFF Nourish Protein Solutions, Memphis, TN

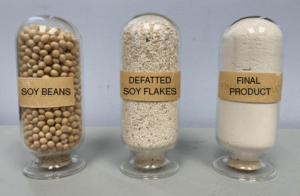

IFF Nourish Protein Solutions manufactures soy protein isolates from the raw material of soybean flakes. The flakes are received on rail cars and processed into protein powder before being packaged into bulk bags.

Products are sold to food and beverage manufacturers for use in infant formulas, yogurt products, soymilks, meats, and other products. Read more at www.iff.com.

How it Started

The first call occurred in 2014 when IFF needed a couple of engineers for plant support. LSI engineers visited the plant, and it was the start of a long and successful relationship.

Client quote:

“Our partnership with LSI began in 2014, since then, we’ve completed (35) PLC-5 to ControlLogix processor conversions and (40) PLC-5 I/O rack conversions, and so many other successful projects. It’s incredible to think about all the work we’ve accomplished, and please know it’s very much appreciated. Looking forward to many more successful projects.”

~ Jonathan L., Automation & Process Control Leader

The Situation

In 2014 the plant was controlled by dozens of Allen-Bradley PLC-5 processors, and IFF’s automation and process control team had begun a migration to Rockwell Automation’s ControlLogix platform. LSI was asked to provide the software engineering effort to convert two PLCs and provide checkout support. This opportunity was a proving ground for LSI and led to more projects. Over the next several years, LSI helped IFF with numerous projects, including:

- Alarm Rationalization and Programming

- PLC-5 Upgrades and IO Conversions

- Safety PLCs

- Construction Planning

- Server Additions and Migrations

- iFIX HMI Development for Process and Packaging Areas

- Centrifuge Upgrade Projects

- Sustainability Projects

- Controls Development for Wastewater Treatment

- Electrical & Instrumentation Design for the Explosion Mitigation System

- Panel Design and Fabrication

- Solenoid Valve Panel Upgrades

- Machine Shop Custom Fabrication

The Aggressive Project Schedule

In spring 2022, LSI performed the largest and most critical projects to date during IFF’s annual outage.

- PLC-5 I/O conversion of over 800 I/O points requiring ten 1756 ControlLogix Racks. The success of this conversion was critical because the system being updated controls the distribution of chemicals and raw materials for the entire plant. Conversion included:

- Verification of all field devices and terminations, update existing drawings, and generate new drawings as needed.

- A post-conversion audit of all terminations, after the I/O was migrated from the 1771 racks to the 1756 racks.

- Startup and commissioning.

- Solenoid Valve Panel Upgrades

- Designed, configured, and facilitated the conversion of 136 valves to ethernet control

- Spray Dryer Wet-down Mitigation

- Designed and programmed controls for automatic drain valves for the high-pressure pumps to minimize wet-down of a spray dryer

- Packer Upgrade

- Provided project engineering support for OEM Packer upgrade and integration with PanelView and Servo controls

- VFD Upgrades

- Upgraded several pumps with VFDs removing the need for control valves while saving energy.

The results

The results of the outage are best described by IFF’s Automation & Process Control Leader, Jonathan L.

“Just wanted to say thank you to the entire LSI team for a successful Spring 2022 outage!!! This was easily our biggest undertaking as a team, and we really shined. I’m proud to be part of such a strong team. It’s a pleasure to work with very talented and like-minded professionals. We all challenge each other and have all become stronger as a team. I also really appreciated the daily morning safety meetings and how we kept safety at the front of everyone’s minds.”

LSI Listens

From the first call for plant support, LSI responded. By understanding IFF’s needs and migration plans, LSI’s experienced team became an essential and ongoing partner. Delivering the outcomes needed for success.