How Can We Create A Distillery That Combines The Benefits Of Craftsmanship With The Advantages Of Modern Automation?

What Our Client Said

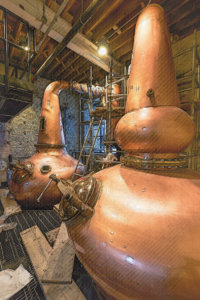

We are a company with a rich history in the distilling business; a history that we wish to resurrect through the launch of Spring Mill Distillery. Our vision is to create a new, state-of-the-art distillery that will combine the 180-year-old artisan distillation processes from our history with the technological and automation efficiencies of modern day. We need a partner with both the necessary experience and relationships to make this vision a reality.

What We Heard

We know LSI’s reputation for successfully integrating modern automation systems with classic brewing and distilling practices, and we need that team of specialists to conceptualize, engineer, procure, construct and oversee the controls and automation of a new, state-of-the-art distillery on a heritage brownfield site. We plan to use top-of-the-line materials from the finest producers of distilling equipment, but we lack the process control connections and industry partners to complete the process. What can LSI do to put it all together?

What We Did

Successfully integrated classic distilling methods and modern automation systems • Provided industry experience and know-how • Ensured the coexistence of productivity and tradition in the final product

LSI became involved with the development of Spring Mill Distillery in the early stages, and what began as a drafting project soon evolved into a full integration and engineering partnership. Working closely with the customer allowed LSI’s engineers to gain a true understanding of what they envisioned in regard to the capabilities and functionality of the future distillery. Once a plan of action was in place, LSI developed a complete set of piping and instrumentation diagrams (P&IDs). These drawings helped the customer to visualize the relationship of equipment to process in the facility and allowed LSI to size and select the pumps, valves and instruments. Throughout the course of the project, LSI utilized its purchasing resources and industry partners to provide Spring Mill Distillery with the best equipment to fit its desired distillery applications. The facility also required an automation platform that could operate effectively and meet safety requirements in both standard and hazardous environments. LSI utilized an Omron PLC platform for plant operations, which provided a technological foundation that could expand as the distiller grew. This system allows the operator to manage key operations manually yet monitor PLC-controlled operations via strategically located HMIs in the plant or even from their tablet.

LSI became involved with the development of Spring Mill Distillery in the early stages, and what began as a drafting project soon evolved into a full integration and engineering partnership. Working closely with the customer allowed LSI’s engineers to gain a true understanding of what they envisioned in regard to the capabilities and functionality of the future distillery. Once a plan of action was in place, LSI developed a complete set of piping and instrumentation diagrams (P&IDs). These drawings helped the customer to visualize the relationship of equipment to process in the facility and allowed LSI to size and select the pumps, valves and instruments. Throughout the course of the project, LSI utilized its purchasing resources and industry partners to provide Spring Mill Distillery with the best equipment to fit its desired distillery applications. The facility also required an automation platform that could operate effectively and meet safety requirements in both standard and hazardous environments. LSI utilized an Omron PLC platform for plant operations, which provided a technological foundation that could expand as the distiller grew. This system allows the operator to manage key operations manually yet monitor PLC-controlled operations via strategically located HMIs in the plant or even from their tablet.

LSI provided:

- Process engineering

- Project management

- Design

- Automation

- Panel building

- Systems integration

- Commissioning

- Continuous improvement

- Site support

The Results Speak For Themselves

Combining the productivity of automation with the one-of-a-kind flavor of hand-crafted spirits

The facility needed an automation platform that allowed for distilling at modern volumes but still allowed key variables to be controlled by distillery personnel. LSI worked with the customer to create a balance where the support operations were automated, but key operations were controlled by craftsmen.

Delivering a complete systems integration solution

LSI’s team successfully integrated brewing and distilling utilities throughout the new facility. Through a combination of process engineering, project management, design, automation, panel building and site support, LSI was able to make the client’s vision a reality.

Connecting to the spirits industry

The customer lacked the necessary resources and vendor relationships to successfully complete the project on its own. LSI utilized its industry partners to provide the customer with the very best equipment for its specific distillery applications.

Making independent decisions that put the distillery first

With LSI’s help, Spring Mill Distillery was able to form important industry partnerships that benefitted from LSI’s support. Because LSI is independent and not owned by a manufacturer, we were able to deliver engineering solutions and the best products for the application.

LSI Listened

LSI listened, then we got to work, utilizing our expertise and relationships in the spirits industry to develop a new distillery that would not only meet customer expectations, but exceed them. LSI worked with the customer along the way, providing technical insight, solutions and answers that helped the overall project progress smoothly. The end result was a new, state-of-the-art distillery with the function and capability to produce a product with the highest standards of quality.

LSI’s team was able to take the customer’s vision and make it a reality, resulting in a successfully launched distillery and a brand-new legacy of creating fine spirits.

To learn more about Spring Mill Distillery and the way they were able to transform a 180-year-old building that once served as a mill and distillery into an ultramodern, state-of-the-art distillery operation, visit: www.springmilldistillery.com/our-story.